Posted by Amy Carbone on Mar 17, 2021 9:00:00 AM

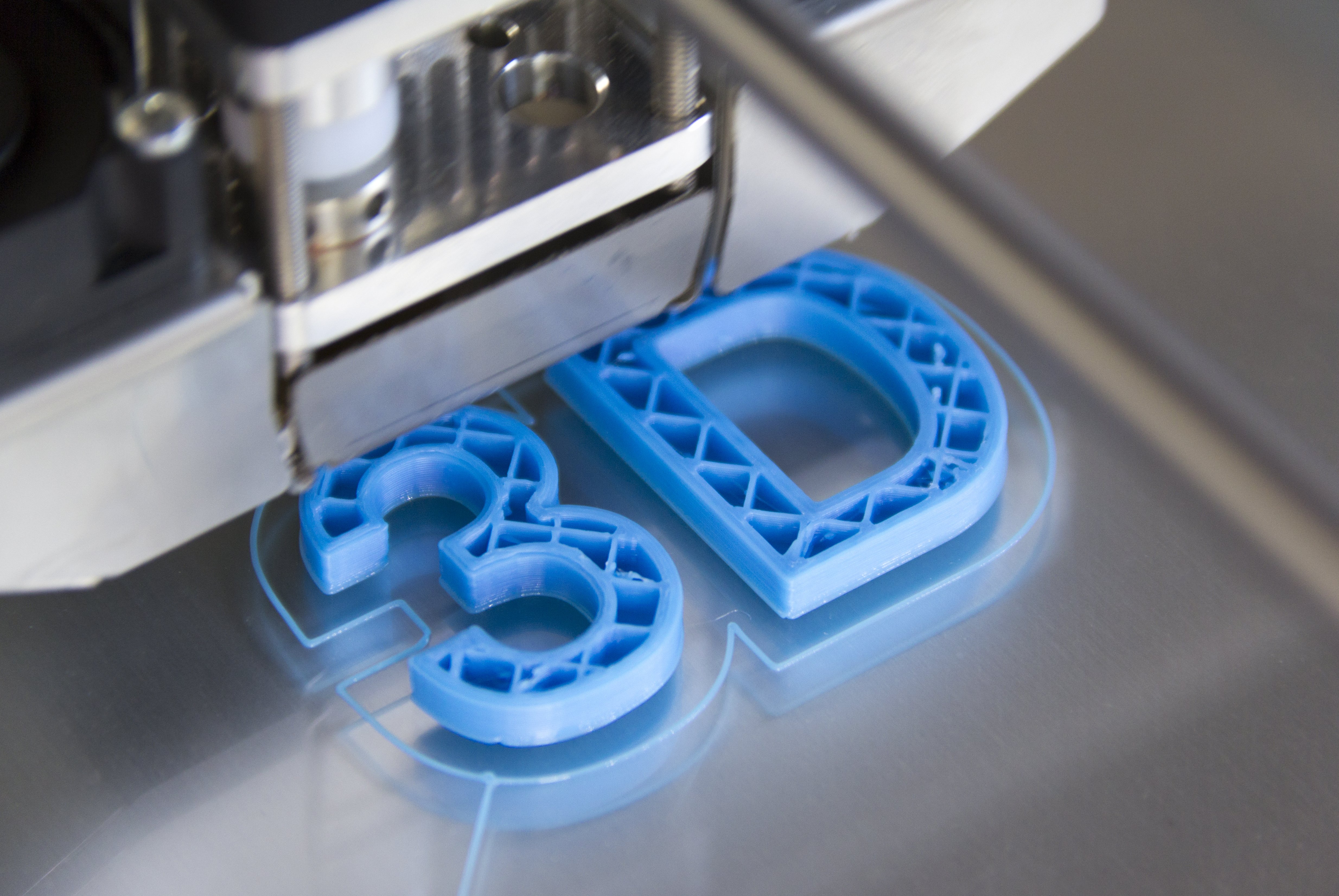

The 3D printing technology within the dental industry is on course to reach $930m by the end of 2025.

Thankfully, 3D printing technology is now more affordable than in its infancy and is becoming more mainstream within dental offices across the nation. The applications of dental 3D printing are far-reaching and its implementation is expected to aid the entire dental industry in a variety of ways.

Learn more about why 3D printing matters to the dental industry every year.

Faster Production

One of the main improvements within the 3D printing industry when it comes to dental needs is the speed of manufacturing. Dentists may now manufacture an appliance while a patient waits in the dental chair. This same day service is expected to dramatically improve the industry and create more availability for this technology in dental offices across the nation.

New Materials

Biocompatible materials are now being used to mimic a ceramic’s aesthetic results. There have also been significant innovations in terms of transparent flexible resins. This could be applied in a wide variety of dental applications. In many cases, the 3D scan will evaluate the current color and shade of adjacent teeth. This means that not only will a tooth-colored implant be created, but it will be the exact color of the patient’s existing teeth, which is much better than the traditional process.

On-Site Dental Implant Production

Another reason why 3D printing matters to dentistry is the ability to print a model, allowing patients to “test drive” their teeth. The printer produces an actual, real-life tooth or implant that the dentist can insert into a patient’s mouth. They are then able to feel the difference such an implant could make.

This innovation will allow the patient to communicate any issues and correct them in real-time. Ideally, this capability will lead more patients to accept implants than when they were unable to feel what a difference replacing a tooth could make.

On-Site Mouthpiece Production

Even though dental laboratory technologists are extremely skillful, there is still room for human error. Conversely, when a dental team can produce a mouthpiece using 3D technology on-site, they can be sure the mouthpiece or orthodontic appliance fits appropriately. In this way, 3D printing removes any possibility of human error.

3D Impression instead of Plaster

The process of using plaster to create an impression is one of the most uncomfortable and messy procedures to undergo. Thankfully, with 3D technology, a mouth can be digitally scanned, which perfectly duplicates the patient’s mouth. This includes their teeth and even their gums. The end result is a much more comfortable and accurate impression of the patient’s teeth, which can then be used to create better fitting appliances and implants.

It Often Adds Longevity to Prostheses

Again, human error comes into play anytime a person is creating a prosthesis or implant. Structural defects or imperfections can lead to a poor fit and can negatively impact the longevity of the implants. Conversely, when 3D printing technology is used to produce a prosthesis, it is structurally more sound and fits better inside the mouth. As a result, prostheses produced using 3D methods tend to last longer than those made using traditional methods.

It’s Better for Patients Overall

Not only do 3D printing methods produce better fitting implants and prostheses, but the fully digital implementation is also a great addition for dental technicians, orthodontists, dentists and the patients they treat for many other reasons.

For example, the process of scanning and then making removable prosthetics is faster than ever before, streamlining the entire process. Long gone are the days where a patient has to come into a dental office, undergo a messy, uncomfortable plastering process, then wait for that impression to be sent to a laboratory for production. This entire process would often take days or even weeks. Now, it all can be accomplished in one visit to a dentist’s office with 3D printing capabilities.

Allows Local Professionals to Access Specialists Worldwide

This technological ability has also expanded the reach of many dental professionals. For example, a local dentist can access specialists from around the world when designing a specific appliance, all without leaving their office. Not only does this expedite the process of producing prostheses for patients, it also makes seeking the skill of a specialist more convenient and affordable.

Dental Field Ahead of The Medical Field by Embracing 3D Technology

The dental field is way ahead of the standard field of medicine when it comes to embracing and utilizing 3D printing technology. For some time, dentists could create patient-specific solutions for various dental issues. After all, there are no “one size fits all” solutions when it comes to implants, mouthguards, dentures or orthodontics as every patients’ mouth is different from every other patient.

In comparison, the general medical field has lagged behind. Medical companies are still making standard issue prostheses, hoping they will work for every patient. The dental field has been utilizing this type of personalized technology for years. With the continued innovation within the 3D printing field, the gap between the two industries just keeps getting wider.

How We Help

We work with dentists all the way through their careers, regardless of the twists and turns that those careers may take. Contact us today to learn how we can become a partner in your journey as a dentist.

Treloar & Heisel and Treloar & Heisel Property and Casualty are divisions of Treloar & Heisel, LLC.

Insurance products are offered through Treloar & Heisel, LLC.

This content is intended for general informational purposes only and should not be construed as advice.

21-019